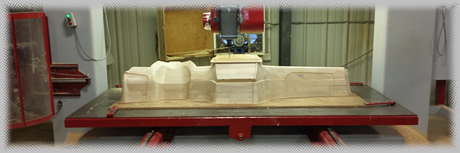

In-House Tooling Excellence

Paramount Plastics has experienced pattern and mold makers in-house, ensuring tooling costs and progress can be closely monitored and revisions handled quickly. Our staff can recommend the proper tooling types and requirements to meet your production tolerances, forecasts, and budgets.

- Custom pattern making

- Mold design and construction

- Rapid prototype development

- Tool maintenance and repair

- Cost-effective solutions